Vishay / BC Components PTCEL Inrush Current Limiting PTC Thermistors

Vishay / BC Components PTCEL Inrush Current Limiting PTC Thermistors provide safe, repetitive inrush current limitation and protection in various high-power applications that require a controlled capacitor charge or discharge function. These thermistors significantly reduce board space and component count because the devices absorb higher energy levels of up to 340J for a single PTCEL17, and the devices operate at high ambient temperatures of up to +105°C. The built-in self-regulated safety mechanism prevents the PTCEL thermistor from overheating in any overload situation. PTCEL thermistors are suitable for controlled charging and discharging high-energy capacitors with voltage levels up to 1200VDC. Resistance values can be selected from a wide range between 60Ω and 1000Ω. These thermistors can be connected in series/parallel to form a network of energy-absorbing thermistors for applications that need higher energy levels or short interval times at higher temperatures.PTCEL thermistors are through-hole mounted to the PCB and can be either PIP reflow soldered or wave soldered. The self-protecting characteristics of ceramic PTC technology prevent any overheating or overloading of the component and limit the current in the circuit to a safe, low level. Charge and discharge energy can be applied to the PTC in short times, ranging from 10ms to a few seconds. The absorbed energy is dissipated away with in a few minutes so the PTC can cool down to ambient temperature and be ready for another inrush current limiting operation. Vishay / BC Components PTCEL thermistors can withstand highly repetitive charge or discharge cycles (>100,000) in automotive or industrial applications. PTCEL13 and PTCEL17 series thermistors are AEC-Q200 qualified, and UL recognized. In addition to off-the-shelf selection, the PTCEL series can be customized to circuit designer specifications, including various resistance values or voltage and energy levels.

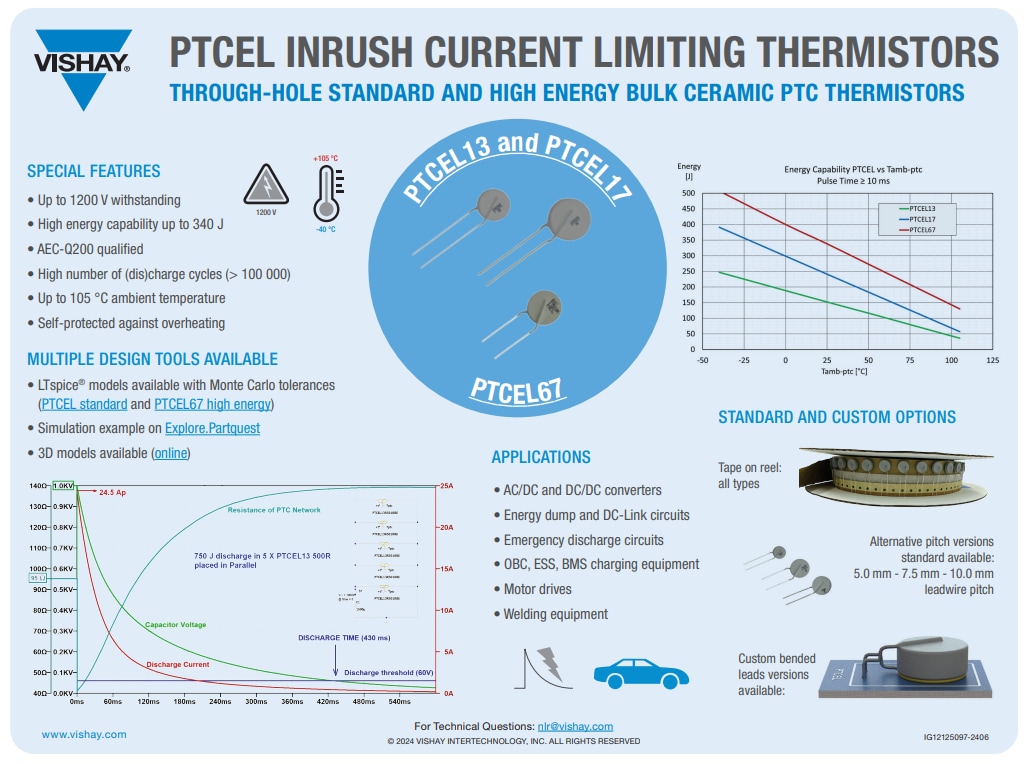

Features

- Up to 340J high energy absorption

- >100,000 inrush-power cycles

- Up to 25kW resistance against non-switching peak-powers

- Up to 1000V direct voltage

- Self-protecting in case of overload with no risk of overheating

- AEC-Q200 qualified

- UL recognized – file E148885 for AC and DC use

- Rugged construction with UL 94V-0-approved coating

Applications

- AC/DC and DC/DC converters

- Load dump and DC-link circuits

- Emergency discharge circuits

- On-Board charger, battery charging equipment

- Motor drives

- Welding equipment

Specifications

- 60Ω to 1000Ω resistance range

- 40A maximum inrush current

- +130°C to +140°C switching temperature range

- 500VDC to 1000VDC maximum DC voltage

- 350VRMS to 700VRMS maximum AC voltage

- 14mW/K to 19.5mW/K dissipation factor

Infographic

Through-Hole Infographic

Mechanical Parameters

Outline & Dimensions

Videos

Additional Resources

- High-Energy Series Datasheet

- eBook: An Automotive Grade Above

- White Paper: Discretely Get Up to 22kW on On-Board Chargers - English

- White Paper: Discretely Get Up to 22kW on On-Board Chargers - Simplified Chinese

- White Paper: Discretely Get Up to 22kW on On-Board Chargers - Japanese

- Engineer's Toolbox - Vishay

- FEVs: On-Board Chargers

- FEVs: HVAC - (P)HEV and EV

- Factory Automation: Motor Drives

- Factory Automation: Air Conditioning Systems

- Fabrication: Welding

- PTCEL Series Product Information

- Did You Know? PTCEL

- Capabilities and Custom Options

- Why it Matters: Automotive Under the Hood